The Eventuri FL5 Carbon Turbo Tube consists of a number of components engineered to perform a specific purpose and fabricated to the highest of standards. We use 100% pre-preg carbon fiber with no fibreglass which means we can achieve a smooth internal surface to maintain smoother airflow. Here are the details for each component and the design ethos behind them:

- Carbon Fiber Turbo Tube

- CNC Machined Turbo Flange

- Custom Silicon Coupler at Turbo Side

Carbon Fiber Turbo Tube

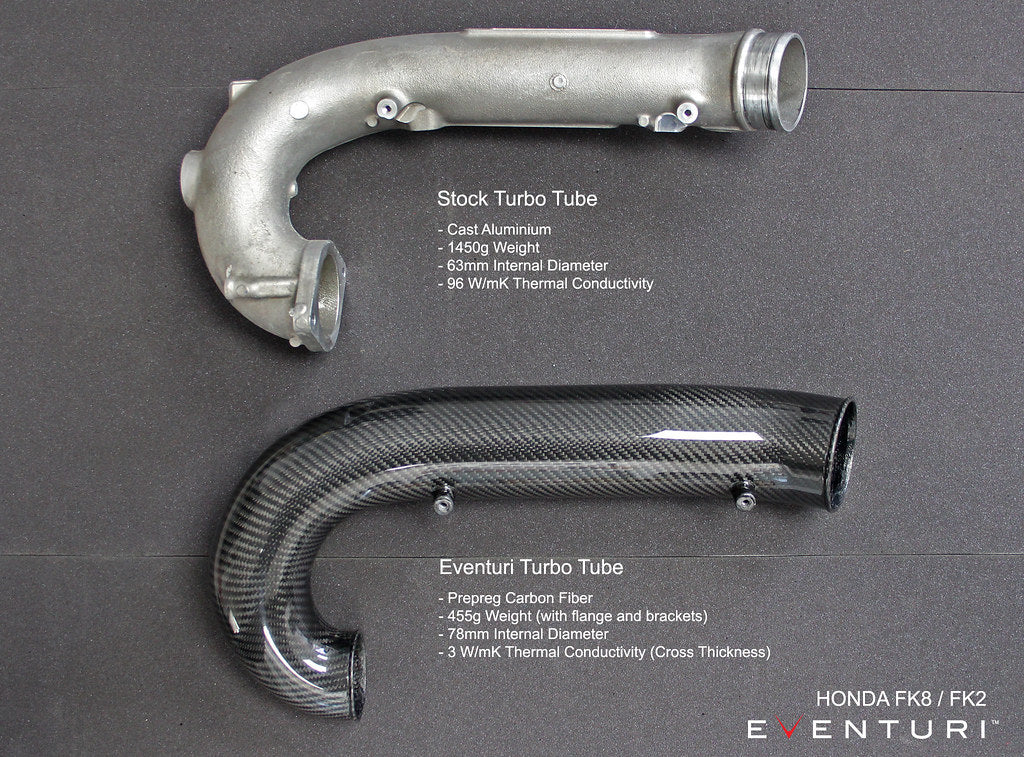

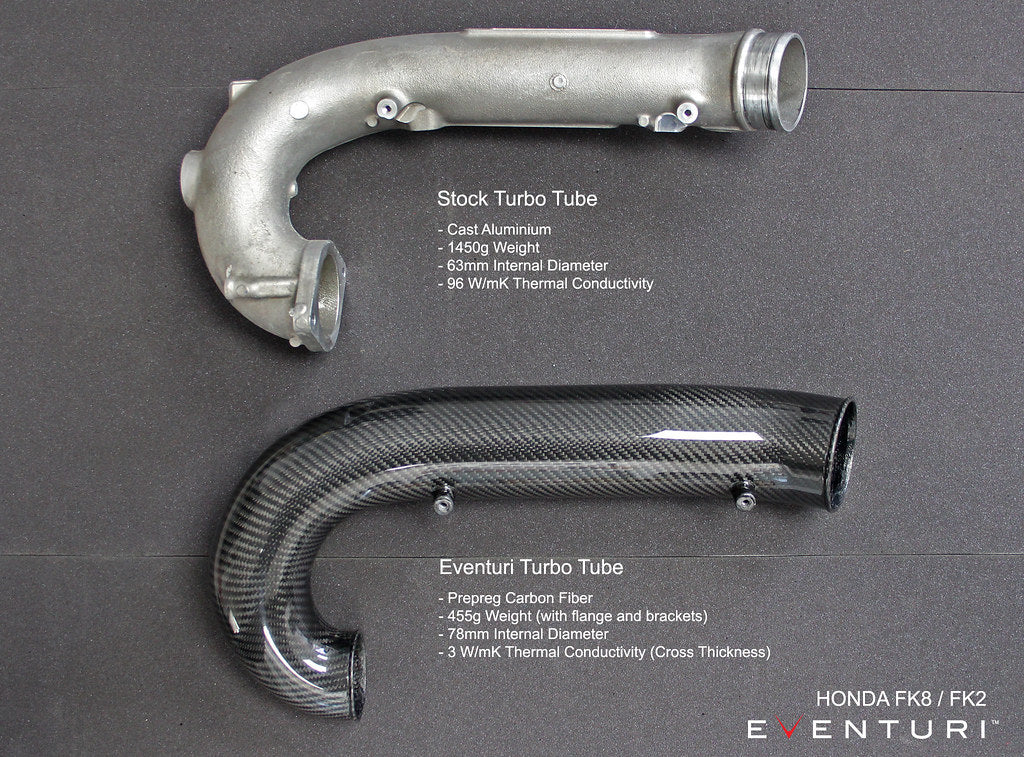

Crafted from Prepreg Carbon Fiber, the Turbo Tube is a one-piece design to maintain a smooth flow path to the turbo. It has an inlet diameter starting at 78mm internally and then increasing to 88mm across the main body of the tube before tapering down to the turbo inlet flange. The stock turbo tube in comparison has an internal diameter of 76.5mm, which stays at that diameter across the main body and then tapers down to the turbo. This difference in size equates to an increase in cross sectional area of over 32% at its largest point. Furthermore, since it is made from Carbon, it has a much lower weight and lower thermal conductivity across the wall thickness than the stock cast aluminium tube. Here is a comparison between our FK8 tube and the OEM version, the same principles apply to the FL5.

Custom Silicon Coupler and Flange

The turbo coupler has a silicon spacer ring which separates the carbon from the metal turbo flange. This acts as a thermal barrier to reduce heat conduction from the hot turbo flange through to the carbon tube. The flange is CNC machined from aircraft grade aluminium and anodised. It provides a perfect fitment and seal against the stock turbo.