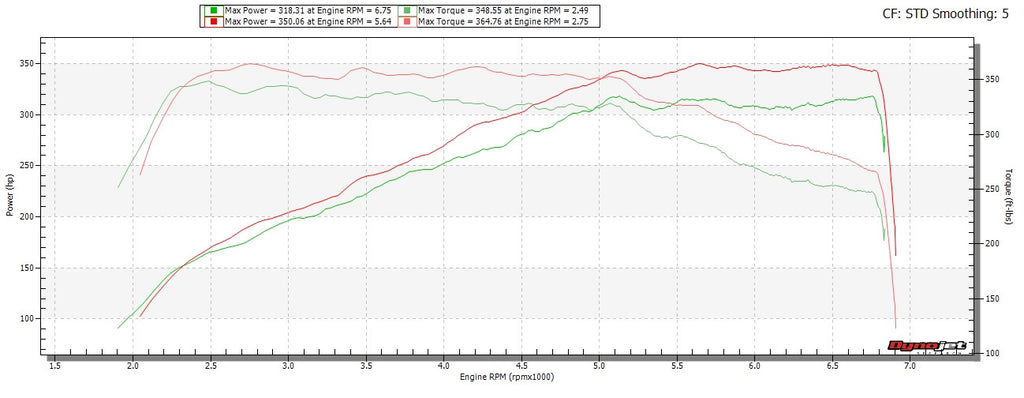

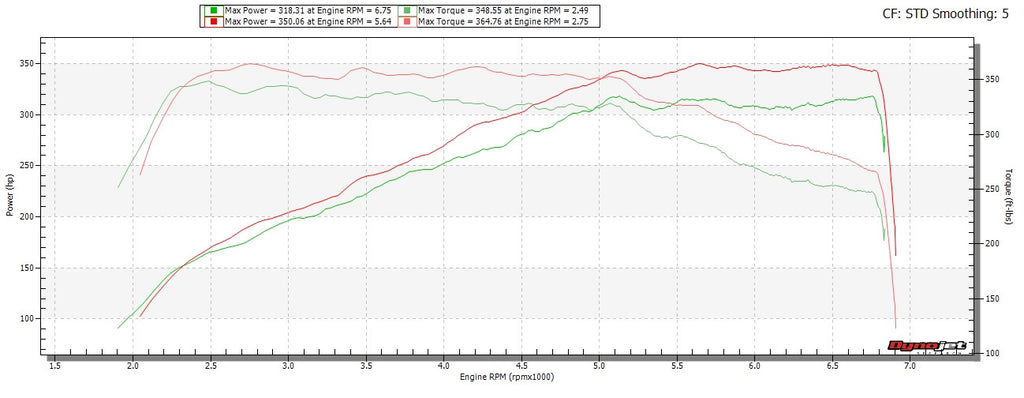

ER B58 4.5" Downpipe Dyno

SO WHY 4.5" PIPING?

The new turbochargers on the B58 engines utilize a much larger 4.5" outlet compared to the 4" outlet on the older N55 engines. If we ran a 4" downpipe flange inlet so that we can use 4" tubing, a "step" would be formed between the turbocharger outlet and downpipe inlet. Exhaust gas for the turbocharger would hit this "step" and a lot of turbulence would form at this point and cause backpressure. Backpressure this close to the turbocharger would greatly affect performance. Thus, to ensure that we get unobstructed flow from the turbocharger outlet to the downpipe inlet, we had to CNC machine a new 4.5" flange to match. This allows a seamless transition and eliminate any possible turbulence which would cause backpressure. Though this presented another challenge for us as 4.5" tubing is not readily available and hard to source. The ER motto "Performance, No Compromise" prevailed at the end and through hard diligence and many phone calls, we finally found a source for the material. Even though the material was considerably more expensive than standard 4" stainless steel, we wanted to give our customers the best by producing the best product possible.

The ER Competition Series Catless Downpipes is constructed out of 100% 304 grade stainless steel and utilize mandrel bent piping. They are 100% TIG welded by ER's in house fabricators and built in the USA. The factory turbocharger turbine housing utilizes a V-Band flange which we have duplicated and CNC machined cut out of billet 304 stainless steel. Stainless Steel CNC machined O2 sensor and laser cut brackets are TIG welded using stainless steel rods. The O2 sensor is positioned at the factory location. Since the outlet of the turbocharger is 4.5" and the factory exhaust system is 3", the factory downpipes reduces size using short transitions from 4.5" before the catalytic convert and 3" afterwards. Due to space needed for the cataylic converter, the factory downpipes reduce in size using very short transitions. Since our catless downpipes delete the cataylic converter, we have more space. Thus, we use very long transitions. These longer transitions allow the exhaust gas time to smoothly transition from the larger piping to the smaller. Also, since we utilize a larger 4.5" pipe right after the turbocharger, turbo backpressure is significantly reduced. This results in less exhaust turbulence and backpressure which again improves throttle response and increase turbocharger spool times (less turbocharger lag).

The ER downpipes are designed to fit perfectly with either the factory exhaust system or your aftermarket exhaust system. There are no compatibility issues whatsover. The downpipes will come by default in Brushed Finish.