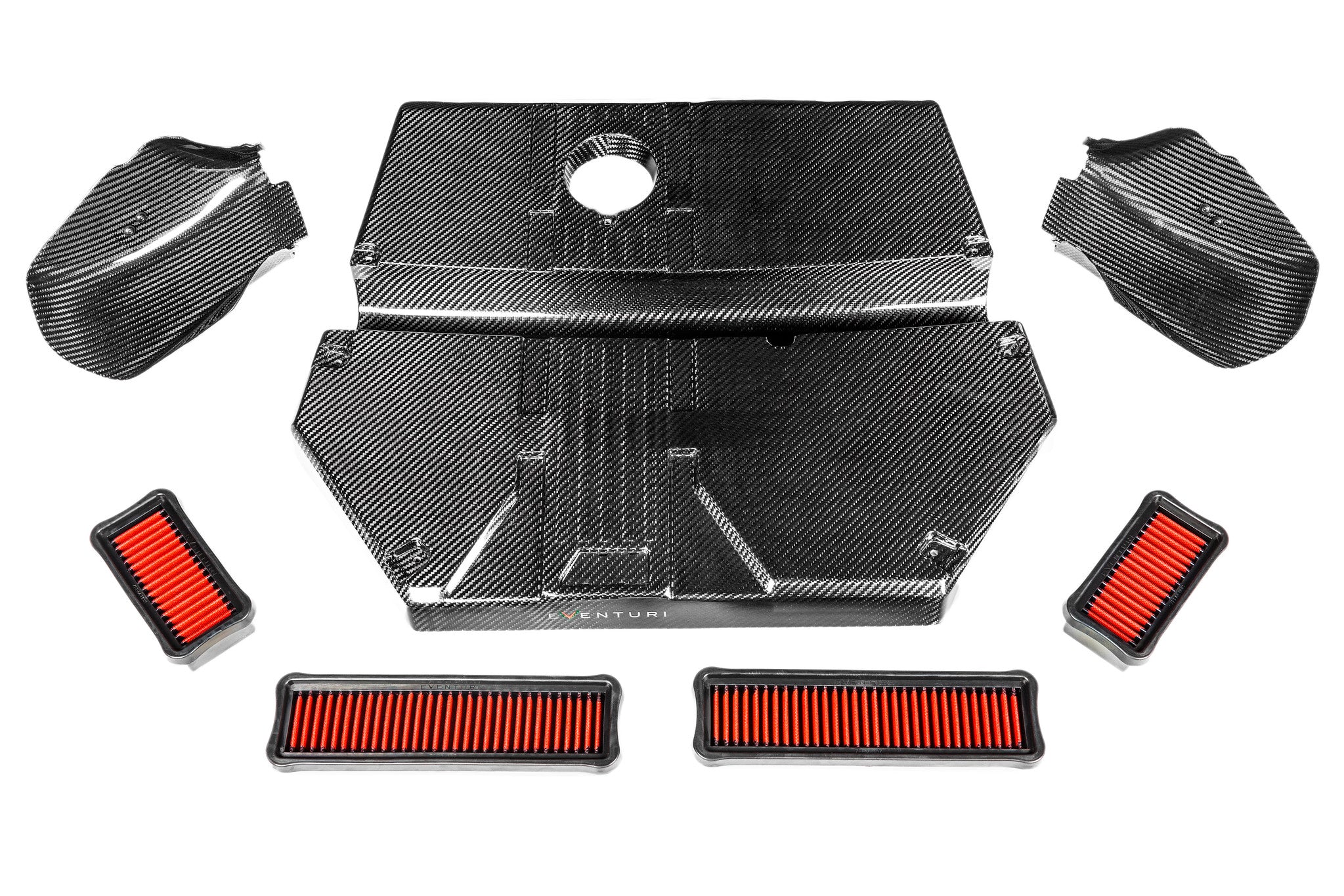

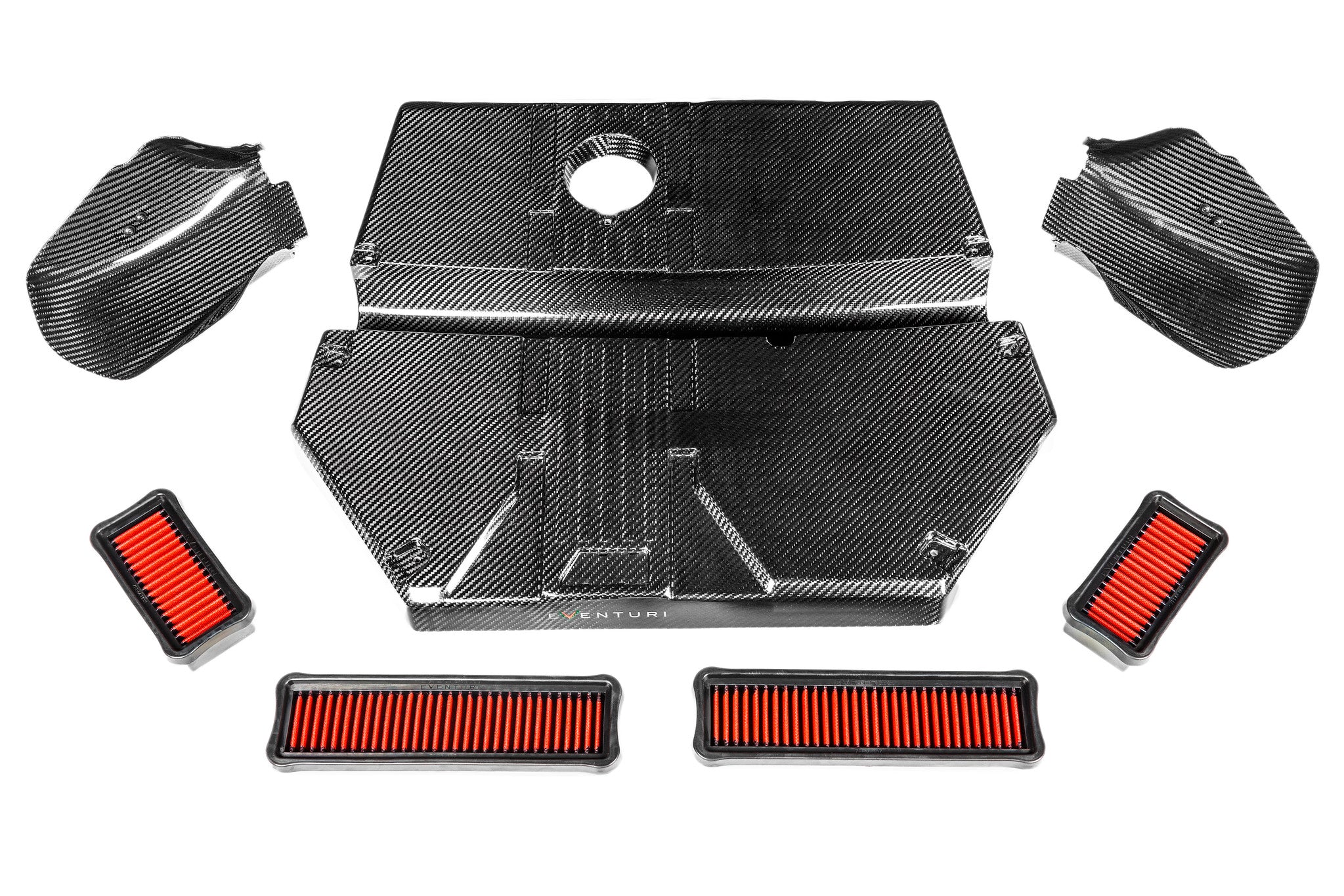

- 1 x Carbon Fiber Airbox Lid

- 2 x Carbon Fiber Air Scoops

- 4 x Direct Replacement High Flow Air Filters

- Laser Cut Stainless Steel Brackets

The Eventuri X3M/X4M intake system consists of a number of components engineered to perform a specific purpose and fabricated to the highest of standards. Here are the details for each component and the design ethos behind them:

The Prepreg carbon fiber airbox lid has been recreated using the same dimensions as the OEM version. There is minimal space above the lid to increase the size and in doing so would also disrupt the airflow path. So we kept the same dimensions and maintained the direct flow path to the filters. Since the lid is made from carbon, it is thinner and lighter than the stock lid and so the induction sound of the engine is more audible.

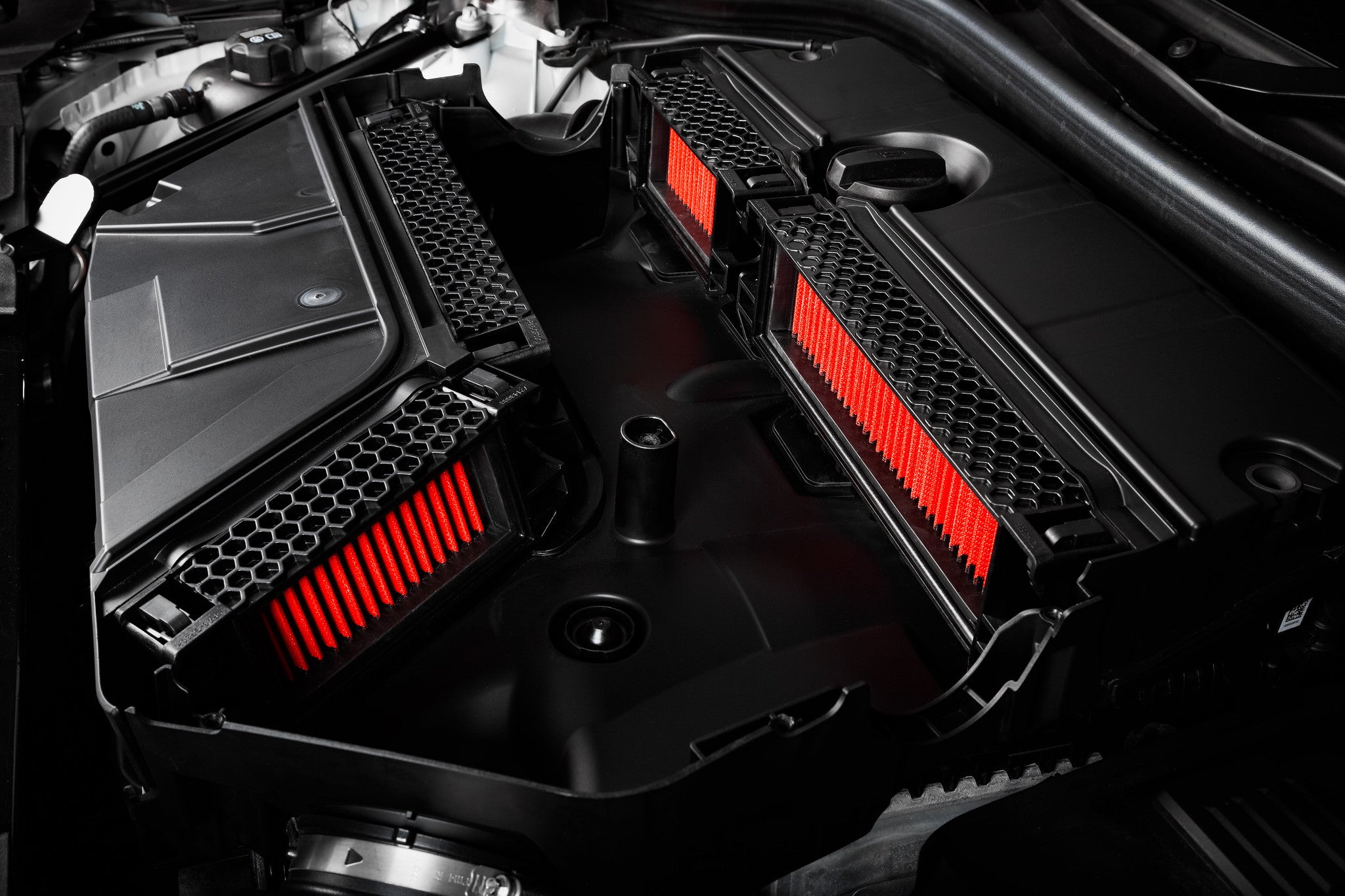

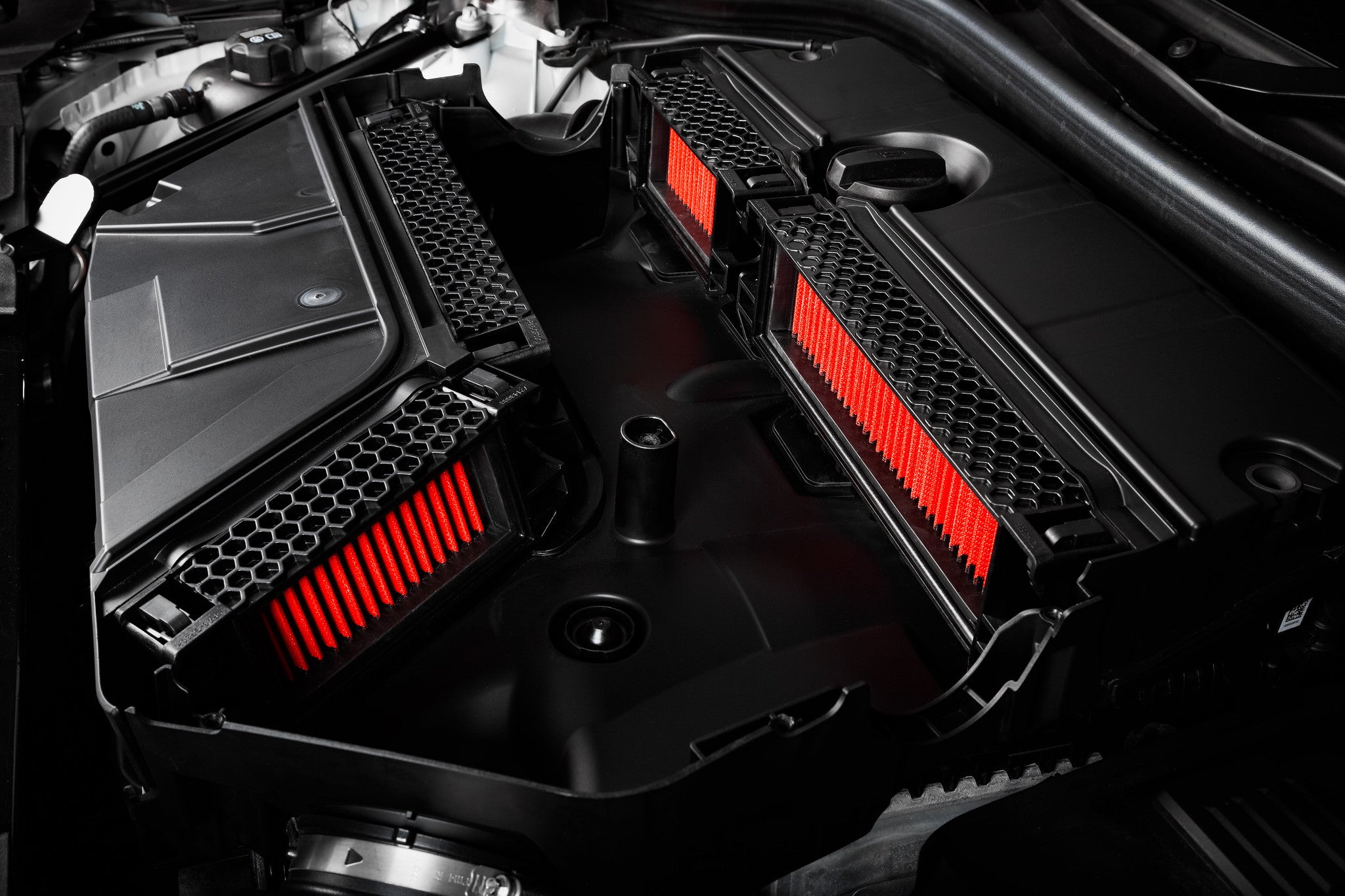

We have redeveloped the OEM panel filters using a high flow non-woven filtration mesh which is encased in a highly durable stainless steel mesh. The filtration element allows for less restriction while maintaining suitable filtration properties. The mesh is captured in a Urethane surround which is very stable at high temperatures and retains its shape to allow for an adequate seal at all times. Each set comprises of 2 small and 2 larger filters which fit perfectly inside the OEM filter cartridges.

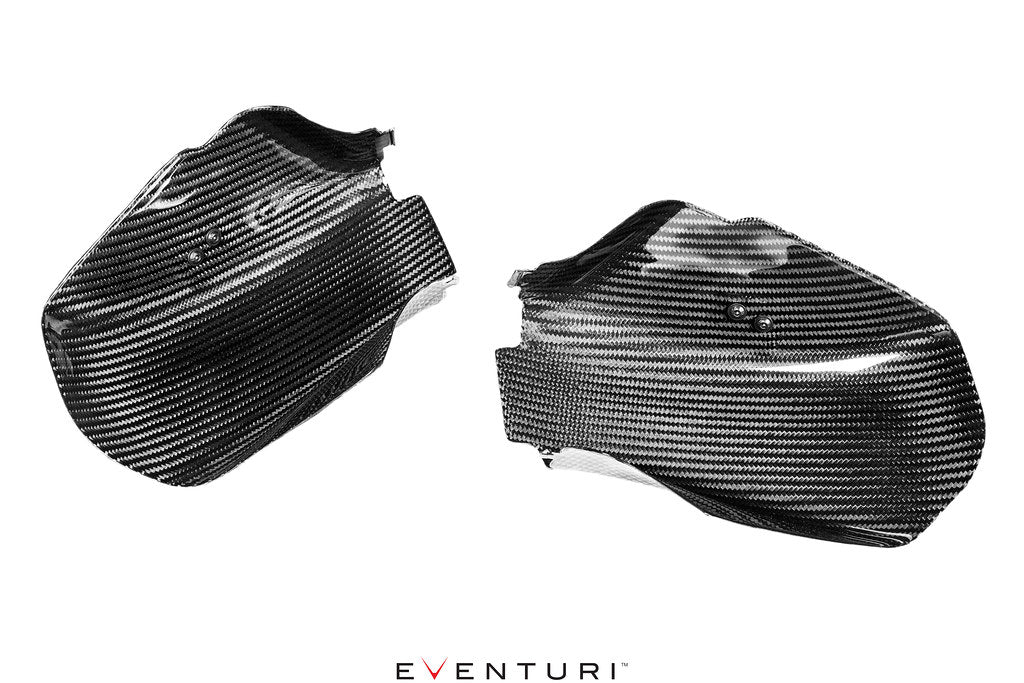

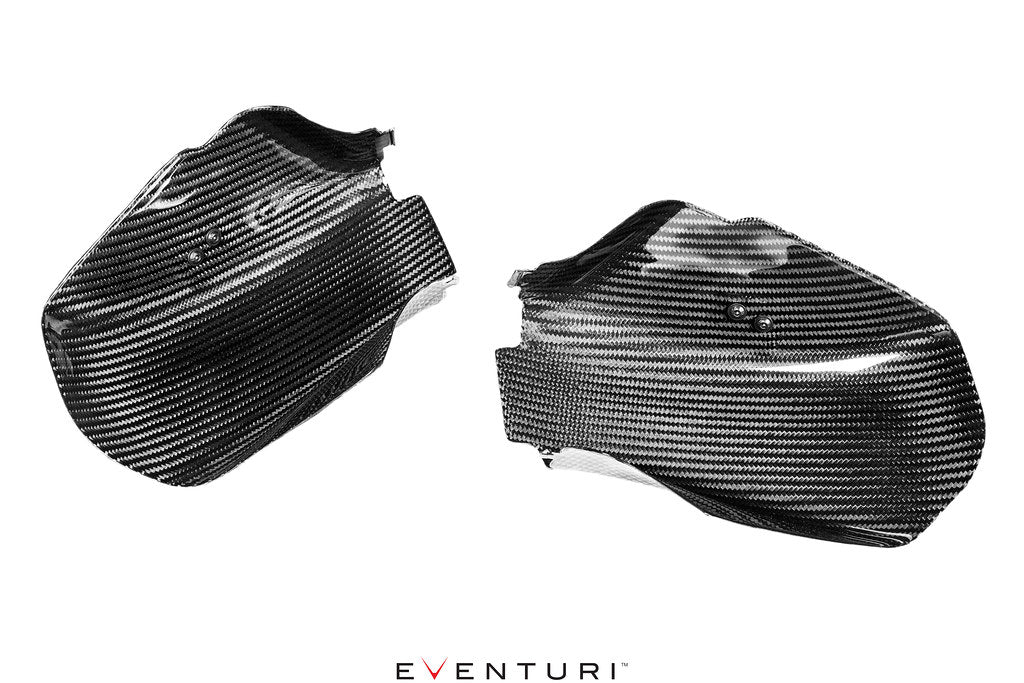

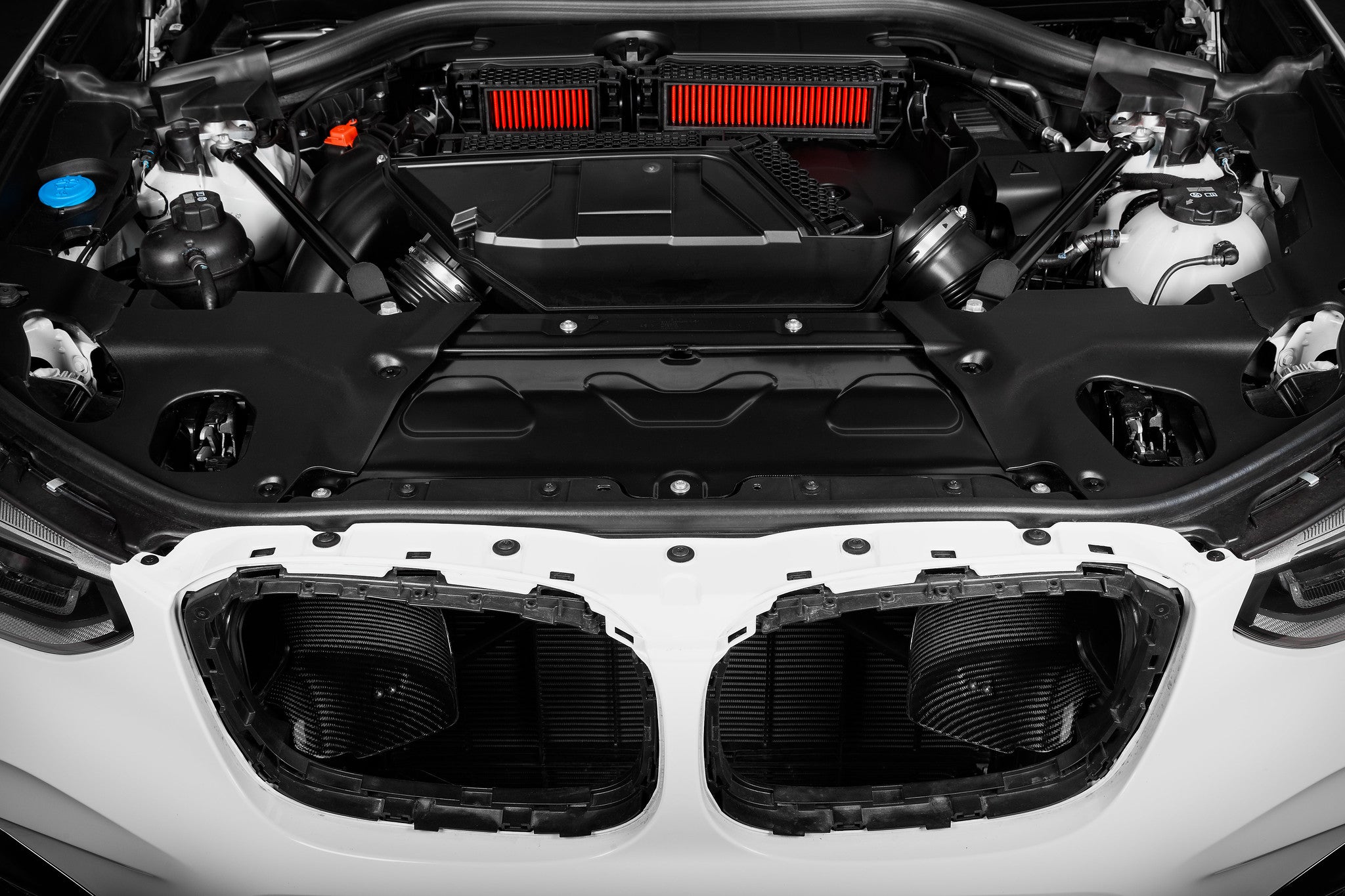

The final carbon components in this system are the front scoops - essential to direct ambient air to the filters.

The scoops were designed for maximum efficiency in directing the incoming air to the stock duct openings. Many aftermarket scoops have a large flat area almost perpendicular to the oncoming air - not great for channeling it into the ducts as the airflow just "hits" this flat portion and creates turbulence.

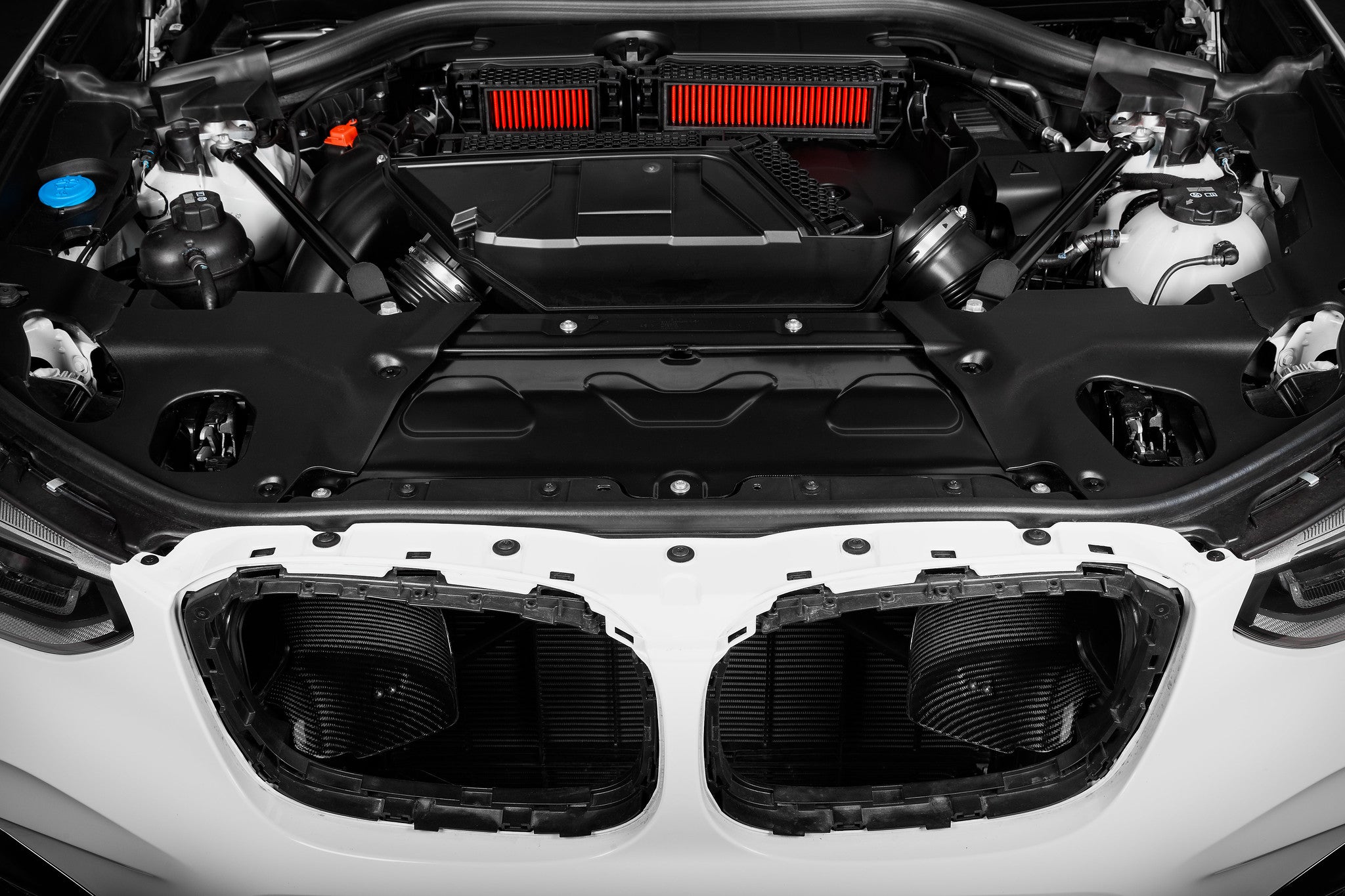

Unlike most aftermarket "scoops" the Eventuri Scoops have been designed extend from the stock duct openings all the way to the grills. In order to capture as much air as possible, the scoops are shaped to the same contours as the outsides of the grills and then smoothly channel ambient air through a continuous curve to the duct openings. CAD images to illustrate the shape:

By Forcing ambient air into the airbox, heat soak is reduced and inlet air temperatures are also reduced.